Bricks are the building blocks of any masonry construction. They are usually made from clay, mud, concrete, or even stone. However, the conventional bricks (called “firebricks”) are made from mud only, created by the action of intense heating and then cooling. Bricks are produced in a brick-factory (also known as brick-field) – a huge area with a furnace at the center of it. There are many such brick factories in West Bengal, supplying the constant demand for bricks. “Sitala” brick-factory is one of such factories situated in Suryapur, North 24 Parganas, West Bengal. With everything in manual labor and only 40-50 workers working on a daily basis, the factory produces 100,000 bricks per month. Here is a collection of photographs from a short visit to that factory.

The brickfields are generally very huge. The furnace and the tall chimney can be seen on the left side of the photo. The bricks are burned in this furnace at 1000 degrees Celsius to achieve strength. Bricks are seen as they are being sun-dried before burning them in the furnace.

This is the first step of the process. The soft mud is dug and sent to this grinder. Here water is mixed and then the mud is ground until it reaches the desired consistency. Two cows pull the shaft that drives the grinder axel.

Hand-pulled carts are used to carry the mud from the grinder to the place where it is cast into a rectangular shape and left for sun-drying.

A worker is seen as he casts the mud into the desired size and shape. A wooden rectangular box is used as the mold. A single worker can produce 250-300 pieces of wet bricks every hour.

A worker shows his gymnastic skills as he takes a break from his work.

A worker poses as he continues casting the bricks.

A man stands in front of the pile of sun-dried bricks.

Men are seen as they unload and arrange the sun-dried bricks into the furnace. Once the bricks are loaded, the whole area will be covered with mud and fire will be lit. It takes 6-7 days of constant burning until the bricks become hard and turn into orange color.

A young worker waits with his cart after the bricks are unloaded inside the furnace.

Once the burning process is over, the bricks are allowed to cool down. Then the bricks are taken out of the furnace. Workers are seen as they are busy removing the fired-bricks from the furnace. They work without any protection and constantly inhaling the dust from the clay and toxic gases from coal-burning.

A lady is seen as she loads the fired-bricks on her head. The fine dust falling from the bricks is constantly inhaled by her. This causes serious diseases like allergy, asthma, lung cancer, etc.

A worker carries the fired-bricks on his head. The bricks need to be removed from the furnace once the burning process is over, and the bricks are cooled down. Once all the bricks are removed, the portion of the kiln is prepared for the next batch.

A man, with his face covered in dust, smiles as he carries the bricks.

The workers who carry the bricks to/from the furnace are paid based on the number of trips they make. As minimum as Rs. 1.80 is paid to them for each trip (carrying 10 bricks per trip). These are the plastic coins of different colors? each color representing different denominations. At the end of the day, they need to redeem the earned coins to get paid.

This lady keeps track of the number of trips being made by the workers. She pays plastic coins to the workers as they complete one trip.

A person is seen as he returns after unloading the dried bricks in the furnace.

A kid is seen as he stands in front of the bricks lying for sun-drying.

Coal is used as fuel for the furnace. The workers constantly supply coals to keep the furnace alive.

A worker is seen as he pours coal into the grinder before supplying it to the furnace. The workers work in such a polluted environment without any proper protection causing permanent damages to their health.

The kids play near the field as their parents work in the factory. Many of these kids are never sent to school nor have basic education.

A woman is seen as she cooks for her family. Many of the workers and their families live in the factory premises or nearby.

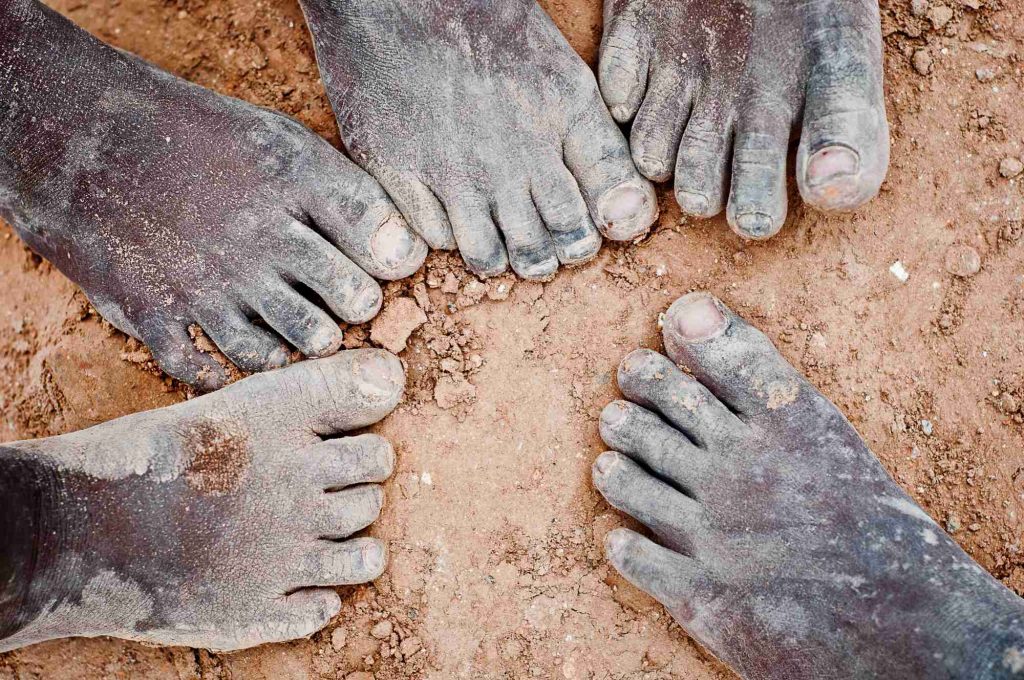

The mud-covered feet of the workers are seen. They work barefoot, continuously inhale fine dust from the clay and noxious gases from the coal-burning kiln; and still, get paid lesser than the minimum wage.